All You Need To Know About Electric Cars

Battery electric vehicles (BEVs) are still in their early stages despite having been around for about as long as gasoline-powered cars, and there is still much to learn about how they function.

Here’s what you need to know about electric cars and how they work.

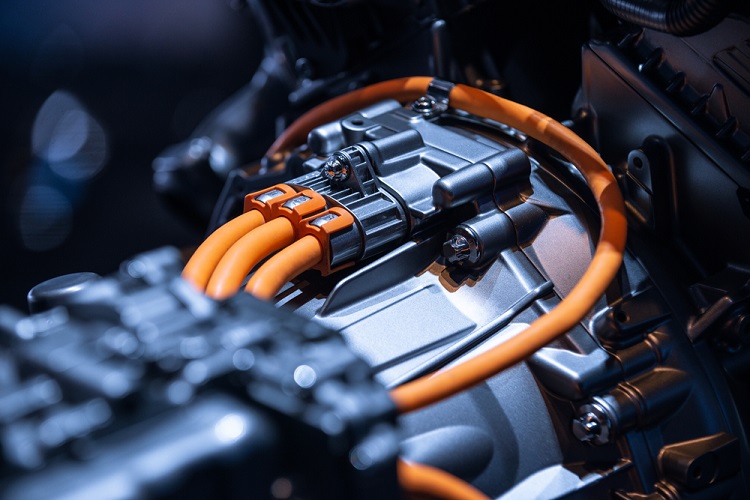

Motors

These days, the majority of manufacturers are producing electric vehicles (EVs) with brushless direct current (DC) motors. These motors do not require the mechanical contact necessary in brushed DC motors since they employ an electronic servo mechanism. For example, brushless motors have a greater power-to-weight ratio than brushed motors, which is a major benefit for EV builders. Friction causes wear on brushed motors as well, and this wear results in dust. The brushes eventually need to be changed.

The induction motor is the third kind of electric motor that EV producers utilize. Because they are extremely economical, provide superior speed regulation, and do away with the bothersome commutators, three-phase alternating current (AC) induction motors are being employed more in the production of electric vehicles (EVs).

A rotating magnetic field is produced in an AC induction motor when the stator winding is linked to a three-phase AC power source. The rotor can remain fixed because of the magnetic field’s rotation. The magnetic field of an AC induction motor uses energy, which is a drawback. The rare earth magnets inside a permanent magnet motor, such as a brushless DC motor, produce an electric field whether or not the car is running.

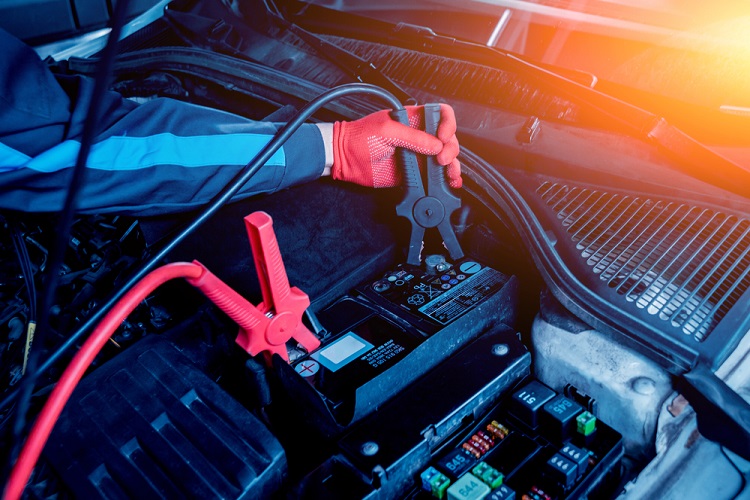

Battery

In stark contrast to your usual lead-acid car battery, these energy storage devices are entirely different. Lithium-ion batteries are the current standard for electrical energy storage in all electric cars. Li-ion batteries have only been around since roughly 1985 and have revolutionized everything since then. The positive electrode for EV batteries is often made of a lithium compound, whereas the negative electrode is typically made of graphite. During discharge, lithium ions go from the negative electrode through an electrolyte to the positive electrode, and then they return during charging.

As energy sources, these rechargeable batteries have many benefits. They don’t have a “memory effect,” have a high energy density, and are resistant to self-discharging over time. If early rechargeable nickel-cadmium batteries weren’t fully discharged before being charged again, they would hold less charge.

One of these batteries would eventually be able to charge to 50% capacity if, for instance, it were attached to a charger while it had 50% of a full charge remaining. This is no longer a problem with Li-ion batteries, which is a crucial convenience for EV charging. Even if filling up at a gas station may be more convenient everywhere, EV owners don’t need to set aside endless amounts of time for charging vehicles overnight at public charging stations in order to prolong the life of their batteries.

Battery Controller

Between the battery and the motor, the battery controller serves as a sort of traffic cop. As long as a battery is connected directly to a motor, it will spin at a speed of about 20,000 RPM with maximum torque. If there is anything visible under an EV’s hood, it’s the battery controller. The battery controller is the brain that controls how the power from all the batteries is sent to the motor, allowing you to utilize it to stop and start in traffic.

Drivetrain

In essence, you could take out the gas engine from your automobile, swap it out for an electric motor, link it to your gearbox, and it would function precisely the same way it does now. However, a typical vehicle’s drivetrain is incredibly inefficient. The drivetrain, or transmission, center differential (if the car has all-wheel drive), and front or rear differentials have drained 15% of the engine’s power by the time it gets to your wheels. When petrol was cheap and plentiful, nobody cared, but losing 15% of your power to spin the gearbox and differential’s gears is unsustainable in the long term.

Some of the earlier EVs used a single motor with drive shafts that powered the front wheels. Then, as things advanced, EV developers began powering the front wheels using two motors, each connected to a wheel by a short driveshaft. Today, manufacturers are increasingly using two, three, or even four-hub motors. Some also use in-wheel motors with no shaft at all; these simply connect to the wheel to provide direct power with virtually no drivetrain loss.

Conclusion

The automotive world is still using fossil fuels. Hopefully, just one more generation will be using the term “gas tank,” while easing into using the term “fuel cell.” Electric vehicles are becoming more popular and are growing better as automakers try to reduce emissions and switch to renewable energy. Think about how fuel efficiency and charging speeds can affect your life, and be ready to consider your options when the time comes.